From : clirik Date : 2018-08-11 16:02

Product Introduction of Calcium Carbonate Roller Mill in Calcium Carbonate Powder Processing Plant:

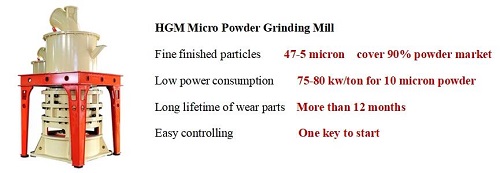

Calcium Carbonate Roller Mill (also called calcite micro-grinding, limestone micro-grinding, calcium carbonate micro-powder mill, talc micro-powder mill, barite micro-powder mill, gypsum micro-powder mill, marble micro-powder mill, feldspar micro-powder mill , fluorite micro-powder mill) is mainly suitable for ultra-fine powder processing of non-inflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, chalk, limestone, dolomite, carbon black, Kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomaceous earth, barite, gypsum, alum, graphite, fluorite, More than 100 kinds of materials such as phosphate rock, potassium ore and pumice, the fine powder finished product can be arbitrarily adjusted between 325-3000 mesh, and the output can reach 0.4-4.5 tons per hour.

Structural composition of Calcium Carbonate Roller Mill

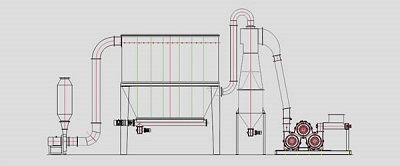

The main part of the limestone superfine grinding machine is composed of a main machine, a reducer, an analysis machine, a fan, a bypass dust collector, a maintenance platform and an electric control cabinet. The auxiliary machine part is composed of a jaw crusher, a bucket elevator, an electromagnetic vibrating feeder, a storage bin and the like.

What should be paid attention to when working with Calcium Carbonate Roller Mill

1. Check the bearing temperature frequently. If the temperature is too high, check whether the lubrication and transmission parts are normal, and whether the rolling distance is too tight. Identify the cause in time and take corresponding measures. If the situation is serious, stop the inspection.

2. Always check the tightness of the belt. If the belt is loose, it will reduce the transmission efficiency and affect the grinding effect. If it is too tight, it will easily cause bearing heat, increase power consumption and reduce the service life of the belt.

3. All kinds of transmission components must be fastened and reliable. Special tools should be used for disassembly or installation. It is forbidden to directly hit with tools such as hammers.

5. Don't forget to check the pneumatic components. After the plastic mill is turned on, always check the pneumatic components in the gas path, whether there is air leakage or damage in the gas path and connection, and check whether the gas supply pressure meets the requirements. The use of the situation should also be checked frequently. If it is found to be too tight, too loose, beating, deviation, and serious wear, it should be adjusted, repaired or replaced in time. The oil quantity of the oil mister in the gas source triplet should be checked regularly, and 20# spindle oil must be added to avoid blockage of the small holes in the pipeline.

The working principle of Calcium Carbonate Roller Mill/Calcium Carbonate Powder Processing Plant:

Calcium Carbonate Powder Processing Plant usually has hammer crusher, bucket elevator, storage bin, vibration feeder, micro-grinding machine, frequency classifier, double cyclone dust collector, pulse dust removal system, high pressure fan, air compressor , electrical control system and other components. The bulk material is crushed by a hammer crusher into a feed particle size (about 1 cm) suitable for the operation of the ultra-fine mill. Then, by adjusting the rotation speed of the mill analyzer, the fineness suitable for the production requirements is achieved, and the bag is manually packaged. It is also possible to configure automatic micro-powder balers and different types of mills as needed.

During operation, the main motor drives the main shaft and the turntable through the reducer, and the roller pin on the edge of the turntable drives dozens of grinding rolls to roll in the grinding ring raceway.

The bulk material is broken into small particles by a hammer crusher and then sent to the storage bin by the hoist, and then passed through the vibrating feeder and the inclined feeding pipe to uniformly feed the material to the bulk disc of the upper part of the turntable.

The material is scattered to the circumference of the circle under the action of centrifugal force, and falls into the raceway of the grinding ring, which is impacted, rolled and ground by the ring roller. After the processing through the three-layer loop, it becomes powder, and the high-pressure fan passes the external air through suction. Inhaled into the machine and the pulverized material is brought into the classifier.

The rotating impeller in the classifier re-grinds the coarse material, and the fine powder that meets the requirements enters the cyclone dust collector with the airflow and is discharged from the lower discharge valve, and the airflow with a small amount of fine dust passes. The pulse dust collector is purified and discharged through a fan and a muffler.

Performance characteristics of Calcium Carbonate Roller Mill:

Calcium Carbonate Roller Mill/Calcium Carbonate Powder Processing Plant Parameter:

| Model | HGM80 | HGM90 | HGM100 | HGM100L | HGM125 |

| Ring Diamater(mm) | 800 | 900 | 1000 | 1000 | 120 |

| Ring Number(layer) | 3 | 3 | 3 | 4 | 4 |

| Roller Number(piece) | 21 | 24 | 27 | 36 | 44 |

| Main Shaft Speed(r.p.m) | 230-240 | 200-220 | 180-200 | 180-200 | 135-155 |

| Input Size(mm) | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 |

| Finished Size(micron/mesh) | 5-47(325-2500) | 5-47(325-2500) | 5-47(325-2500) | 5-47(325-2500) | 5-47(325-2500) |

| Capacity(t/h) | 0.5-4.5 | 0.6-6.5 | 0.7-7 | 1-8.5 | 1.5-12 |

| Overall Dimension(LxWxH,m) | 13.9x4x6.2 | 14.7x4.8x7.2 | 18x4.6x8.6 | 18x4.6x8.6 | 14x9x10.25 |

| Power(KW) | 123-143 | 168.35 | 221.6 | 243.95 | 344.4 |

Last:Zeolite Powder Processing Plant & Zeolite Roller Mill

Next:What Are The Types Of Grinding Operation Of The Three-rings Roller Mill?

Copyright © 2013 Clirik All Rights Reserved