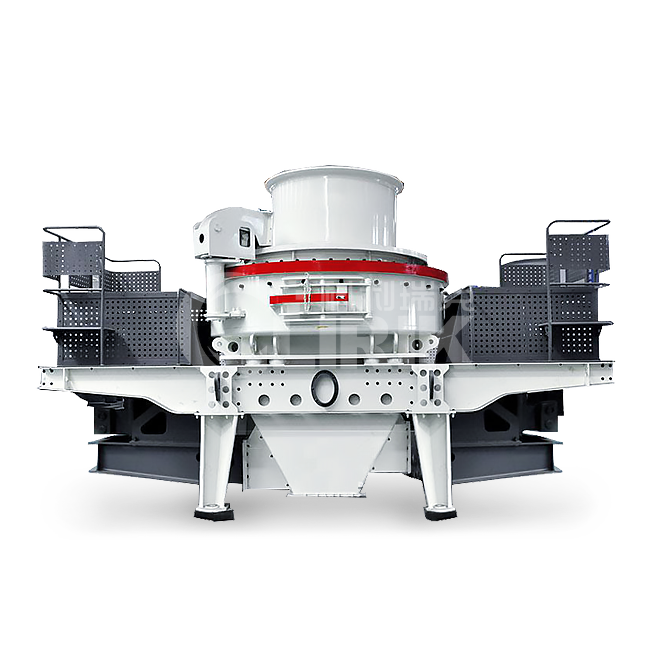

Sand Making Machine from CLIRIK is a newly equipment with international advanced level, it is both a stone crushing machine and shaper machine. VSI Crusher is called Sand Making Machine, also called Shaper Machine and Sand Making Machine

Sand washer is used for removing dust in sand. It aims at improving the quality of sand. It is especially applicable to wash construction sand and paving sand. Sand washing machine is widely used for cleaning materials in the following indus

New type of high efficiency and energy saving is the most advanced domestic reversible euro fine crusher, the fine crusher is mainly used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramic industries as

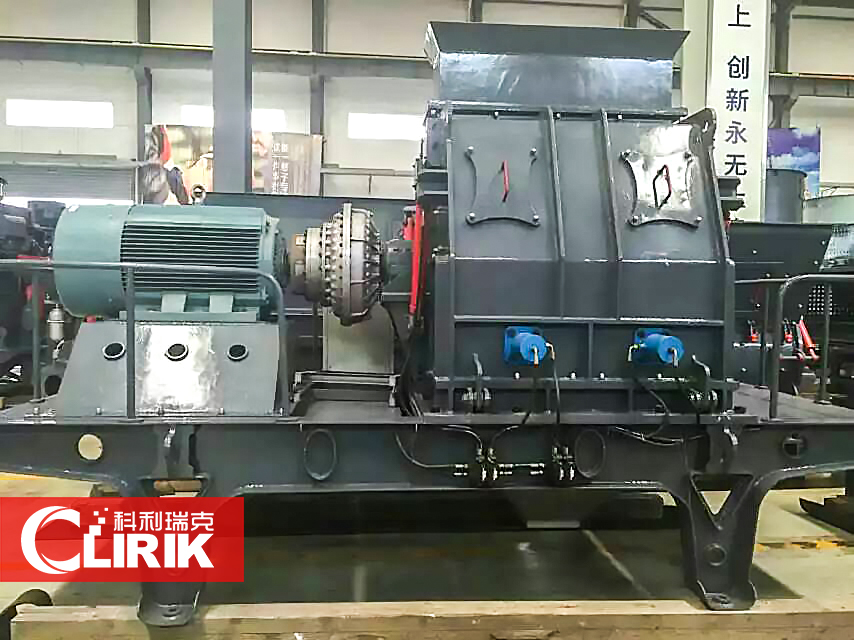

The PC Heavy Duty Hammer Crusher is a new product in the hammer crusher range. The utility model overcomes the problem that the material humidity is blocked greatly, improves the utilization rate of the hammer head, reduces the frequency of

The European version coarse grinding-rough powder grinding machine is widely used in industrial and mining enterprises such as metallurgy, mining, chemical, cement, coal dry stone, construction, sand making, refractory materials and ceramics

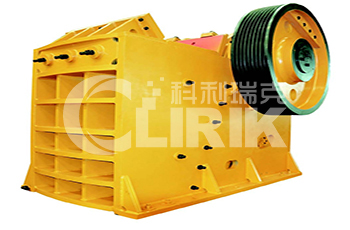

The deep cavity fine jaw crusher series has the characteristics of large crushing ratio, uniform product size, simple structure, reliable operation, simple maintenance and economical operation. Therefore, the crusher is widely used in many

The crusher is a machine for crushing and grinding various materials. The cone crusher is a kind of crusher equipment. It is suitable for crushing raw materials in metallurgy, construction, road construction, chemical and silicate industries

The ball mill is the key equipment for crushing the material after it has been crushed. It is widely used in the production of cement, silicate products, new building materials 52555, refractory materials, fertilizers, black and non-ferrous

The impact crusher can process materials with a side length of 100-500 mm, a compressive strength of up to 350 MPa, a crushing ratio, and a cubic particle after crushing. Widely used in building materials, ore crushing, railways, highways

Processing petroleum coke can choose the mill equipment : YGM high pressure suspension roller Raymond mill : processing fineness between 15-425 mesh (fineness can be adjusted freely), HGM three-ring medium speed superfine mill : The processi

Processing graphite can choose the mill equipment: YGM high pressure suspension roller Raymond mill : processing fineness between 15-425 mesh (fineness can be adjusted freely), HGM three-ring medium speed superfine mill : processing The fine

The main component of limestone is calcium carbonate (CaCO3). Lime and limestone are used extensively as building materials and are important raw materials for many industries. Limestone can be directly processed into stone and fired into qu

Clirik high pressure suspension grinding mill is suitable for processing various non-flammable and non-explosive mineral materials...

Product description of YGM8314 Raymond Mill : Clirik high pressure suspension grinding mill is suitable for processing various non-flammable and non-explosive mineral materials with Mohs hardness less than 9.3 and humidity less than 6%

Roller mill is a highly efficient grinding equipment which is widely used in cement, chemical industry. shanghai clirik have clumsy series vertical roller mill can be used to cement process betterly

The mineral talc powder modification machine,talc powder surface coating machine, widely used in the fields of non-metal stuffing or pigment like plastic, rubber, adhesive, macromolecule materials, high polymer composite, functional material

Beneficiation of Iron Ore. Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice. This also applies to iron ores of the non-magnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up...

Check now

Ore Grinding Mills. Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration (gravity or flotation) or cyanidation. Practice varies, depending upon the type of ore and the amount of reduction required.

Check now

autogeneous grinding of iron ore PF Impact Crusher CS Cone Crusher HJ Series Jaw Crusher HPC Cone Crusher PE Jaw Crusher PFW Impact Crusher HPT Cone Crusher PEW Jaw Crusher HST Con. ALKALINE AND ACID PRESSURE OXIDATION OF PRECIOUS METAL-. ores, concentrates, tailings, and other valuable . semi-autogeneous, or non-autogeneous crushers, .(iron ...

Check now

The energy consumption of ore comminution, especially of the grinding processes, is about to rise in the next years, due to well-known reasons. Deteriorating ore grades force the mining companies to mine and process more raw material to ensure that the refining industry …

Check now

Research of iron ore grinding in a vertical-roller-mill. The total energy consumption for ore comminution will further increase within the next decades. One contribution to minimise the increase is to use more efficient comminution equipment. Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology.

Check now

Beneficiation of Iron Ores. Jaw, gyratory, cone, and roll crushers are used for ore crushing. Semi autogenous grinding and autogenous grinding circuits are used for grinding the ore. Both rod mills and ball mills are used for this purpose. Capital investment and operation costs of …

Check now

iron ore grinding ball mill | Mining, Crushing, Milling. Iron ore Ball Mill … the balls to … Ball Mill For Grinding Iron Ore, Provide Best Price Ball Mill For Grinding Iron Ore Products. Enjoy Best Buy.

Check now

Reducing Grinding Energy and Cost -Magnetite Iron Ore Design Case Study ... Comparing Grinding Options. Proceed ings of Iron Ore 2009 ... The temperature of the hydrothermal fluid during the iron ...

Check now

Iron Ore Mining Equipment Beneficiation process of the three most critical process: Crushing process, Milling process, Screening process and Flotation process. We are one of the leading manufacturer and exporter of Mineral Ore Beneficiation Plant and Machines, fabricated from …

Check now

A SAG mill with a 44' (13.4m) diameter and a power of 35 MW (47,000 HP) has been designed. Attrition between grinding balls and ore particles causes grinding of finer particles. SAG mills are characterized by their large diameter and short length as compared to ball mills.

Check now

Beneficiation of Iron Ore. Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice. This also applies to iron ores of the non-magnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up...

Check now

Ore Grinding Mills. Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration (gravity or flotation) or cyanidation. Practice varies, depending upon the type of ore and the amount of reduction required.

Check now

autogeneous grinding of iron ore PF Impact Crusher CS Cone Crusher HJ Series Jaw Crusher HPC Cone Crusher PE Jaw Crusher PFW Impact Crusher HPT Cone Crusher PEW Jaw Crusher HST Con. ALKALINE AND ACID PRESSURE OXIDATION OF PRECIOUS METAL-. ores, concentrates, tailings, and other valuable . semi-autogeneous, or non-autogeneous crushers, .(iron ...

Check now

The energy consumption of ore comminution, especially of the grinding processes, is about to rise in the next years, due to well-known reasons. Deteriorating ore grades force the mining companies to mine and process more raw material to ensure that the refining industry …

Check now

Research of iron ore grinding in a vertical-roller-mill. The total energy consumption for ore comminution will further increase within the next decades. One contribution to minimise the increase is to use more efficient comminution equipment. Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology.

Check now

Beneficiation of Iron Ores. Jaw, gyratory, cone, and roll crushers are used for ore crushing. Semi autogenous grinding and autogenous grinding circuits are used for grinding the ore. Both rod mills and ball mills are used for this purpose. Capital investment and operation costs of …

Check now

iron ore grinding ball mill | Mining, Crushing, Milling. Iron ore Ball Mill … the balls to … Ball Mill For Grinding Iron Ore, Provide Best Price Ball Mill For Grinding Iron Ore Products. Enjoy Best Buy.

Check now

Reducing Grinding Energy and Cost -Magnetite Iron Ore Design Case Study ... Comparing Grinding Options. Proceed ings of Iron Ore 2009 ... The temperature of the hydrothermal fluid during the iron ...

Check now

Iron Ore Mining Equipment Beneficiation process of the three most critical process: Crushing process, Milling process, Screening process and Flotation process. We are one of the leading manufacturer and exporter of Mineral Ore Beneficiation Plant and Machines, fabricated from …

Check now

A SAG mill with a 44' (13.4m) diameter and a power of 35 MW (47,000 HP) has been designed. Attrition between grinding balls and ore particles causes grinding of finer particles. SAG mills are characterized by their large diameter and short length as compared to ball mills.

Check nowCopyright © 2013 Clirik All Rights Reserved