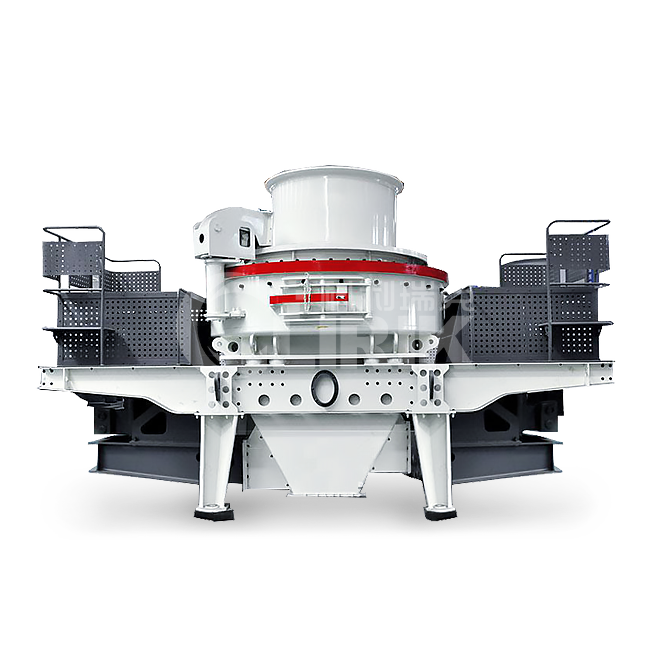

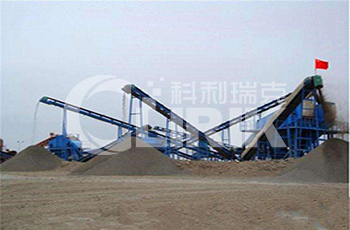

Sand Making Machine from CLIRIK is a newly equipment with international advanced level, it is both a stone crushing machine and shaper machine. VSI Crusher is called Sand Making Machine, also called Shaper Machine and Sand Making Machine

Sand washer is used for removing dust in sand. It aims at improving the quality of sand. It is especially applicable to wash construction sand and paving sand. Sand washing machine is widely used for cleaning materials in the following indus

New type of high efficiency and energy saving is the most advanced domestic reversible euro fine crusher, the fine crusher is mainly used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramic industries as

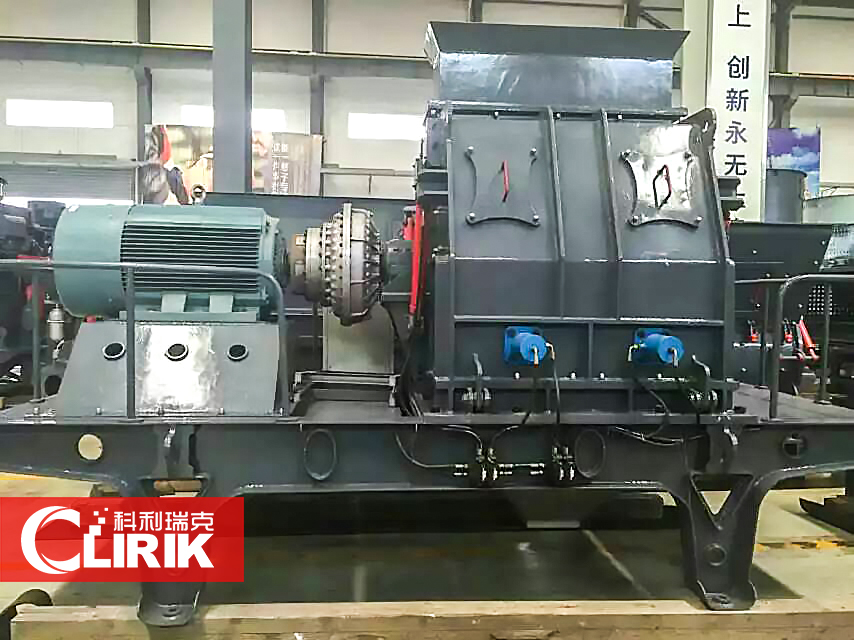

The PC Heavy Duty Hammer Crusher is a new product in the hammer crusher range. The utility model overcomes the problem that the material humidity is blocked greatly, improves the utilization rate of the hammer head, reduces the frequency of

The European version coarse grinding-rough powder grinding machine is widely used in industrial and mining enterprises such as metallurgy, mining, chemical, cement, coal dry stone, construction, sand making, refractory materials and ceramics

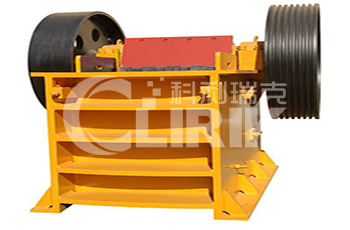

The deep cavity fine jaw crusher series has the characteristics of large crushing ratio, uniform product size, simple structure, reliable operation, simple maintenance and economical operation. Therefore, the crusher is widely used in many

The crusher is a machine for crushing and grinding various materials. The cone crusher is a kind of crusher equipment. It is suitable for crushing raw materials in metallurgy, construction, road construction, chemical and silicate industries

The ball mill is the key equipment for crushing the material after it has been crushed. It is widely used in the production of cement, silicate products, new building materials 52555, refractory materials, fertilizers, black and non-ferrous

The impact crusher can process materials with a side length of 100-500 mm, a compressive strength of up to 350 MPa, a crushing ratio, and a cubic particle after crushing. Widely used in building materials, ore crushing, railways, highways

Processing petroleum coke can choose the mill equipment : YGM high pressure suspension roller Raymond mill : processing fineness between 15-425 mesh (fineness can be adjusted freely), HGM three-ring medium speed superfine mill : The processi

Processing graphite can choose the mill equipment: YGM high pressure suspension roller Raymond mill : processing fineness between 15-425 mesh (fineness can be adjusted freely), HGM three-ring medium speed superfine mill : processing The fine

The main component of limestone is calcium carbonate (CaCO3). Lime and limestone are used extensively as building materials and are important raw materials for many industries. Limestone can be directly processed into stone and fired into qu

Clirik high pressure suspension grinding mill is suitable for processing various non-flammable and non-explosive mineral materials...

Product description of YGM8314 Raymond Mill : Clirik high pressure suspension grinding mill is suitable for processing various non-flammable and non-explosive mineral materials with Mohs hardness less than 9.3 and humidity less than 6%

Roller mill is a highly efficient grinding equipment which is widely used in cement, chemical industry. shanghai clirik have clumsy series vertical roller mill can be used to cement process betterly

The mineral talc powder modification machine,talc powder surface coating machine, widely used in the fields of non-metal stuffing or pigment like plastic, rubber, adhesive, macromolecule materials, high polymer composite, functional material

Grinding machine. A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear deformation. Grinding is used...

Check now

A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a type of machining using an abrasive... Grinders and Grinding Machines Information on GlobalSpec. Description.

Check now

Types and Uses of a Grinding Machine. Belt grinding is a versatile process that involves several kinds of applications such as stock removal and finishing. A jig grinder is used for finishing jigs, dies, and fixtures. It grinds holes and can be used for complicated surface grinding and finishing work.

Check now

Grinding machine. All of the many types of grinding machines use a grinding wheel made from one of the manufactured abrasives, silicon carbide or aluminum oxide. The wheel is manufactured by mixing selected sizes of abrasive granules with a bonding agent (such as clay, resin, rubber, shellac, or silicate of soda) and fusing them together by baking...

Check now

UNITED GRINDING is your grinding solutions partner. We offer services that will assist you throughout the entire life cycle of your cnc grinding machine . Our services include machine installation, training, applications support, preventive maintenance, parts and repair services.

Check now

Facts About a Surface Grinding Machine Posted on March 15, 2013 by Yash Shah To give a meticulous smooth finish to the surface, as regards the level, size or finish of the surface of a flat metallic or non-metallic object, surface grinding tools are used.

Check now

Apr 10, 2019 · The facts and the information in respect to the Grinding-polishing Machine market are taken from authentic sources as like journals, websites, …

Check now

Sep 20, 2005 · Grinding (abrasive cutting), an abrasive machining process that uses a grinding wheel as the cutting tool Grinding machine, used in a machining operation to refine the surface of materials Angle grinder, a handheld power tool. Bench grinder, a benchtop power tool.

Check now

How to Use a Surface Grinder Machine: A surface grinding machine is used to produce a smooth accurate finish on either metallic or nonmetallic materials. It uses a round rotating abrasive grinding wheel that remains stationary (but rotating) while the feed table (with work attached) is run in a reciprocating motion (left and right) under the ...

Check now

Grinders and Grinding Machines Information. Grinders and grinding machines use an abrasive that is bonded to a wheel, belt or disc to remove material and improve surface finish. Devices can be pneumatically driven or powered by a combustion engine or electric motor. Grinders and grinding machines can use single-phase or three-phase power...

Check now

Grinding machine. A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear deformation. Grinding is used...

Check now

A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a type of machining using an abrasive... Grinders and Grinding Machines Information on GlobalSpec. Description.

Check now

Types and Uses of a Grinding Machine. Belt grinding is a versatile process that involves several kinds of applications such as stock removal and finishing. A jig grinder is used for finishing jigs, dies, and fixtures. It grinds holes and can be used for complicated surface grinding and finishing work.

Check now

Grinding machine. All of the many types of grinding machines use a grinding wheel made from one of the manufactured abrasives, silicon carbide or aluminum oxide. The wheel is manufactured by mixing selected sizes of abrasive granules with a bonding agent (such as clay, resin, rubber, shellac, or silicate of soda) and fusing them together by baking...

Check now

UNITED GRINDING is your grinding solutions partner. We offer services that will assist you throughout the entire life cycle of your cnc grinding machine . Our services include machine installation, training, applications support, preventive maintenance, parts and repair services.

Check now

Facts About a Surface Grinding Machine Posted on March 15, 2013 by Yash Shah To give a meticulous smooth finish to the surface, as regards the level, size or finish of the surface of a flat metallic or non-metallic object, surface grinding tools are used.

Check now

Apr 10, 2019 · The facts and the information in respect to the Grinding-polishing Machine market are taken from authentic sources as like journals, websites, …

Check now

Grinding (abrasive cutting), an abrasive machining process that uses a grinding wheel as the cutting tool Grinding machine, used in a machining operation to refine the surface of materials Angle grinder, a handheld power tool. Bench grinder, a benchtop power tool.

Check now

How to Use a Surface Grinder Machine: A surface grinding machine is used to produce a smooth accurate finish on either metallic or nonmetallic materials. It uses a round rotating abrasive grinding wheel that remains stationary (but rotating) while the feed table (with work attached) is run in a reciprocating motion (left and right) under the ...

Check now

Grinders and Grinding Machines Information. Grinders and grinding machines use an abrasive that is bonded to a wheel, belt or disc to remove material and improve surface finish. Devices can be pneumatically driven or powered by a combustion engine or electric motor. Grinders and grinding machines can use single-phase or three-phase power...

Check nowCopyright © 2013 Clirik All Rights Reserved