Work Principle of Roll Mill

From : clirik Date : 2013-08-10 09:04

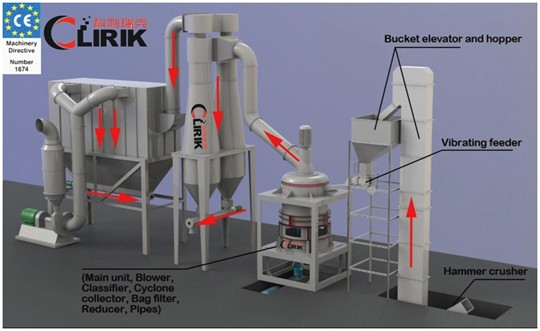

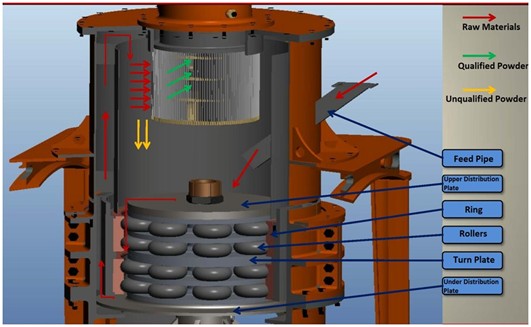

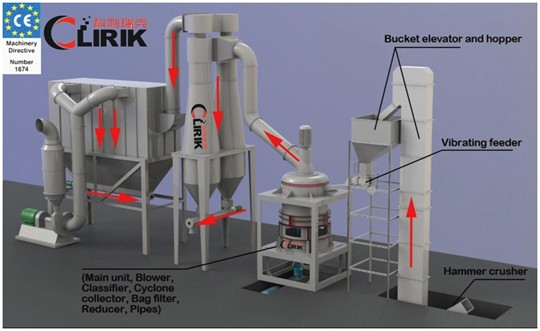

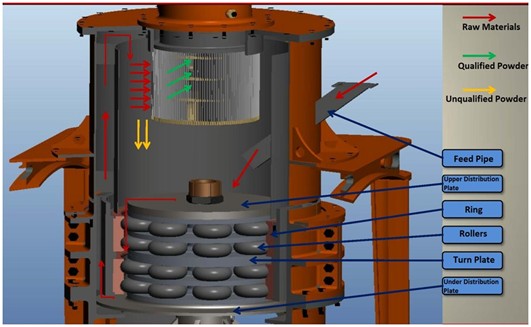

The materials crushed by crusher being sent to the upper distribution plate by vibrating feeder and sloping feeding pipe. When the grinding mill is at work, the main bearing and the turn plate are driven by the electric motor through reducer, all the grinding rollers will roll in the ring channel driving by bearing through plunger, material in the upper distribution plate will be driven in the edge of the turn plate By centrifugal force and fall down into the grinding chamber, where the materials will be pressed, crushed and grinded by rollers repeatedly

The high –pressure air blower constantly inhale the air in the machine, the airflow with crushed materials are brought to the high-speed impeller of the classifier, the high seed impeller will screen the airflow, the unqualified powder will fall down and return to the mill to de re-grinded. The qualified powder mixed with airflow will go into the cyclone powder collector.

When the main unit is at work, the main bearing and dials are driven by the electromotor through reducer, and all the rollers are rolling in the grinding ring driven by the dial through plunger. the material fall down will be driven to the edge of the upper distribution dial by the centrifugal force, and fall down to the grinding ring where the material are repeatedly pressed ,crushed and grinded by the roller.The high pressure air blower constantly inhale air from outside, the airflow with grinded materials go into classifier, the high speed impeller will screen the powder, the unqualified powder fall down to be grinded again, while the qualified powder mixed with air will go into the double cyclone collector, most of the powder fall down and exit from the discharging valve; a small proportion of the fine powderGo into the dust cleaner, and clings to the surface of filter bag, the powder clings to the surface filter bag fall down by the sudden vibration of the filter bag, cause by the high-pressure gas instantly ejected by the pulse valve.In addition, the filter clean air will be emitted from the air outlet of muffler in the end.

Last:The Requirements for Roll Mill

Next:The Material of the Roll Mill Process