YGM series Raymond roller mills Introduction

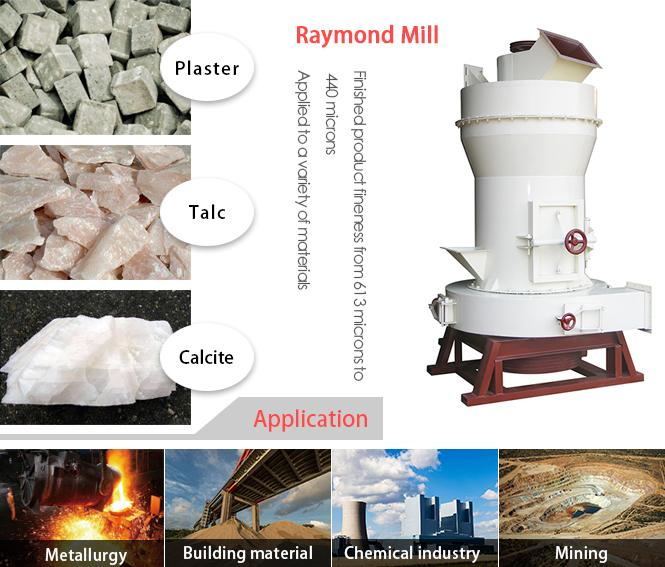

Raymond mill is widely used in dolomite, limestone, potassium feldspar, barite, calcite, talc, marble, fluorite, activated clay, activated carbon, bentonite, kaolin, cement, gypsum, glass, etc. Mohs hardness is not more than 9.3 Grade, high-fine powder processing of more than 280 kinds of materials in non-flammable and explosive mineral, chemical, construction and other industries with a humidity below 6%. The R-Raymond mill is arbitrarily adjusted within the range of 80-325 mesh. Some materials can be as high as 600 mesh.

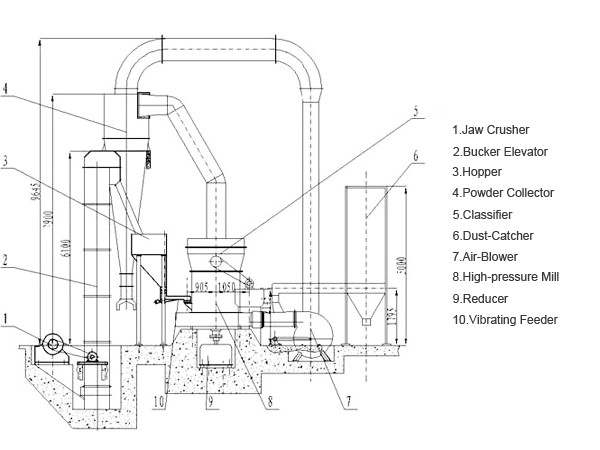

YGM series Raymond roller mills structure

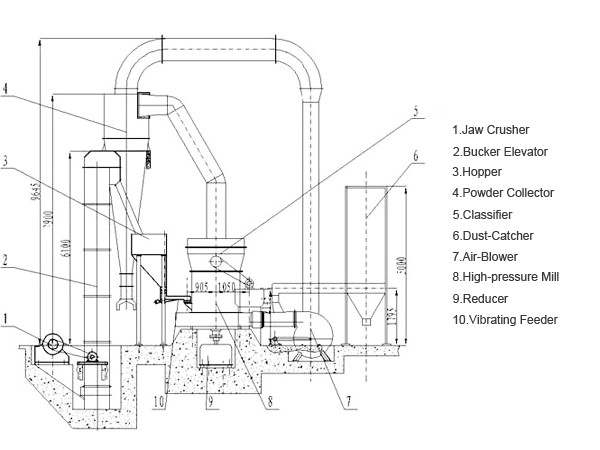

The structure of the Raymond mill is mainly composed of a main machine, an analyzer, a fan, a finished cyclone separator, a fine powder cyclone separator and a duct. Among them, the main body is composed of a frame, an inlet volute, a blade, a grinding roller, a grinding ring and a cover.

The mill produced by the company adopts the advanced structure of similar products at home and abroad, and is updated and improved on the basis of Raymond mill in the same industry. The equipment is more efficient than ball mill, low power consumption, small floor space and one-time investment. small. The grinding roller is tightly pressed on the grinding ring under the action of centrifugal force, so that when the grinding roller and the grinding ring are worn to a certain thickness, the yield and fineness of the finished product are not affected. The replacement cycle of the grinding roller and the grinding ring is long, so that the shortcomings of the replacement cycle of the wearing parts of the centrifugal pulverizer are eliminated. The air-selected airflow of the machine is circulated and flowed in the fan-grinding shell-cyclone-fan, so it has less dust than the high-speed centrifugal pulverizer, the operation workshop is clean, and the environment is non-polluting.

YGM series Raymond roller mills performance advantages

Raymond mill is designed with its unique structure to make it take up less space, convenient transportation, installation, operation and maintenance, and adopt PLC electrical automation control to effectively reduce equipment failure rate and labor cost. High production, production, and a good production environment with zero noise and zero pollution. In addition, the grinding fineness of Raymond mill can be adjusted freely between 80-800 mesh, and the applicability is more flexible and extensive. Overall, Raymond Mill is the best choice for non-metallic ore milling.

YGM series Raymond roller mills working principle

When the Raymond machine is working, the material to be crushed is fed into the machine from the feeding hopper on the side of the hood, and the grinding roller device suspended on the main stand of the main machine is revolved around the vertical axis, while rotating itself, due to the centrifugal force during rotation. The action of the grinding roller swings outward, pressing against the grinding ring, so that the blade shovel the material between the grinding roller and the grinding ring, and the purpose of pulverizing the material is achieved by rolling rolling of the grinding roller.

YGM series Raymond roller mills grinding process

After the material is ground, the fan blows the wind into the main casing, blows up the powder, and sorts it through the analyzer placed above the grinding chamber. The material with too fineness falls into the grinding chamber and re-grinds, and the fineness meets the specifications. It enters the cyclone collector with the wind flow, collects it and discharges it through the powder outlet, which is the finished product. The wind flow is returned to the fan by the return air pipe at the upper end of the large cyclone collector. The air path is circulated and flows under the negative pressure state. The increased air volume of the circulating air path is discharged through the exhaust pipe between the fan and the main engine, and enters the small cyclone collection. The device is cleaned.

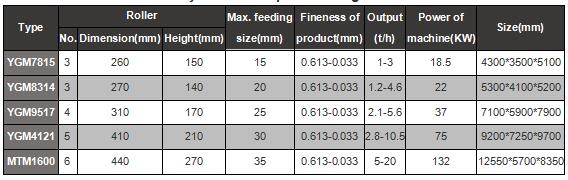

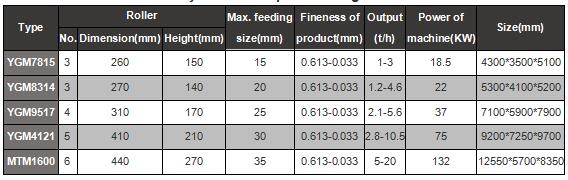

YGM series Raymond roller mills Technical Parameters

Our company is a professional Raymond mill manufacturer, which produces a series of milling equipment, high-pressure mill, high-strength mill, etc. It has won national patents many times and its products are sold to more than 30 countries and regions. The price of the mill is reasonable and has been well received by customers.