What Machines Used In Talc Production?

From : clirik Date : 2018-07-11 08:43

Machines used in

the

production of talc are

jaw crusher & fine powder Raymond roller mill.

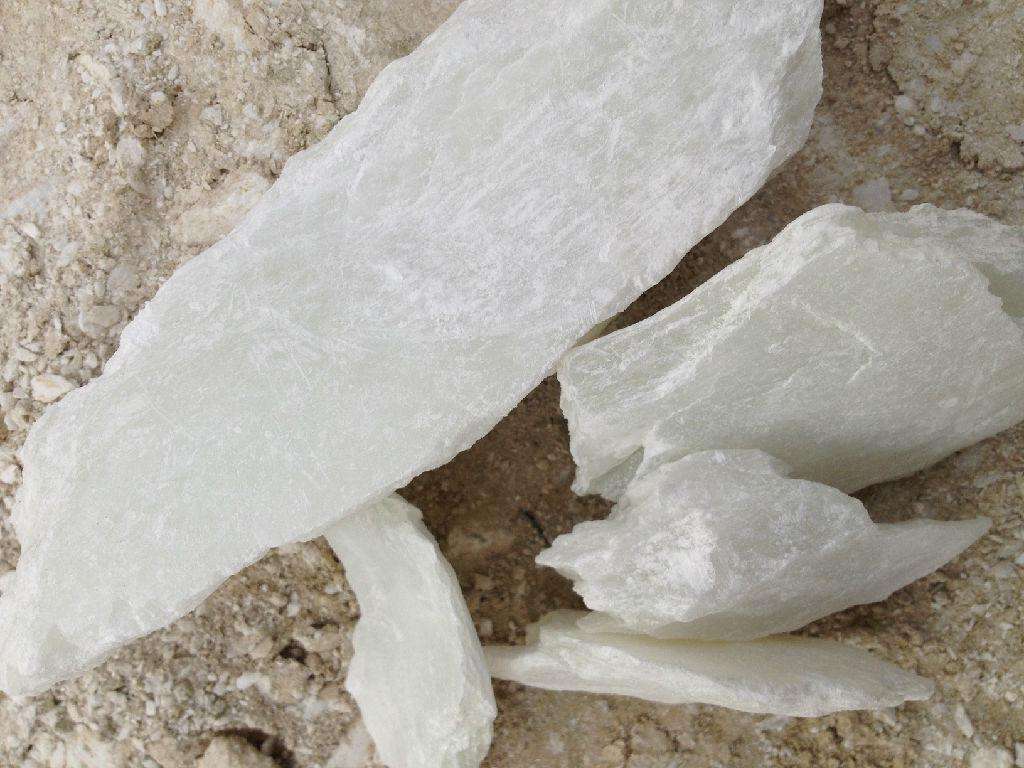

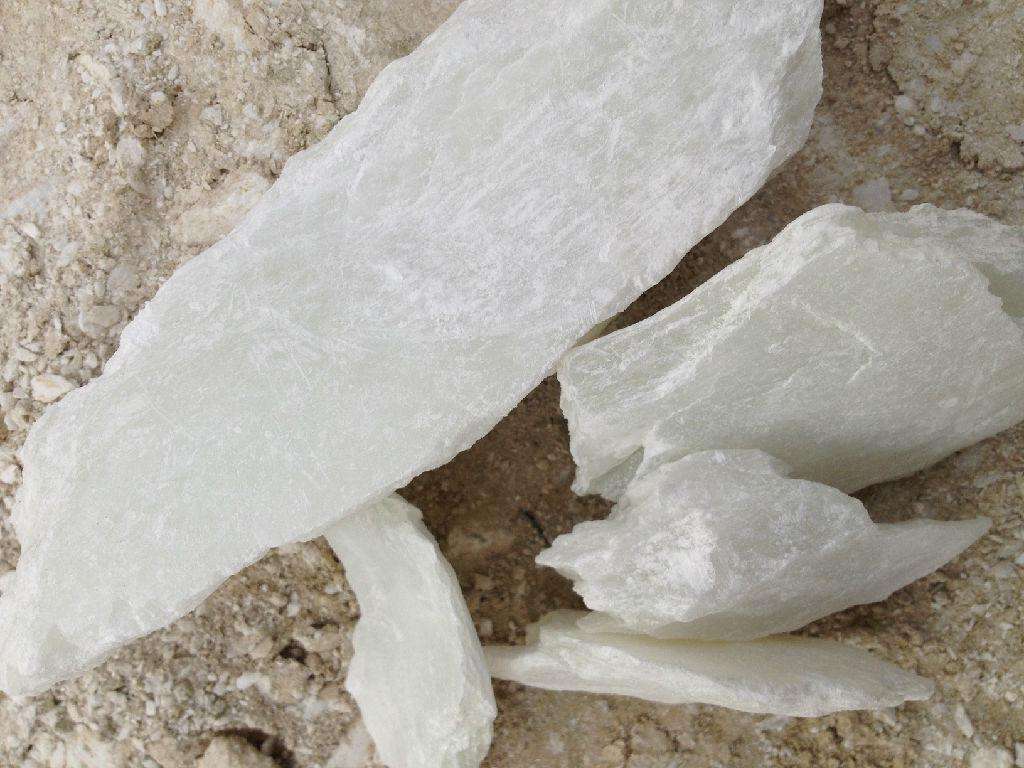

Talc is a kind of stone, but it is the softest stone. You can leave scratches on the talc with your fingernails. Soft talc can also be used instead of chalk! Talc contains a large amount of

silicon, which has the function of blocking infrared rays. It can be added to cosmetics to enhance its sunscreen and anti-infrared properties.

Talc is a common silicate mineral, generally in the form of massive, leafy, fibrous or radial, white and grayish white. There are many uses of talc, such as refractory materials, medicine, paper, rubber fillers, pesticide absorbents, leather coatings, cosmetic materials and engraving materials. As a strengthening and modifying filler, it increases the stability of the product, increases the strength and color. Degree, granularity, etc. Talc is also an important ceramic material used in ceramic billets and glazes. High temperature does not change color, whiteness is enhanced after calcination, density is uniform, gloss is good, and surface is smooth.

After a series of processing, the talc can be ground into a fine powder, that is, talc powder. The most suitable talc powders on the market are 200 mesh, 325 mesh, 500 mesh, 600 mesh, 800 mesh, 1250 mesh, etc. It can be seen that the deep processing of talc requires different types of milling machines. 200 mesh and 325 mesh talc powder can be processed by Raymond mill and high pressure suspension roller mill. The talc powder of 500 mesh, 600 mesh, 800 mesh and 1250 mesh can be produced by ultrafine mill. The talc production process mainly refers to the purpose of grinding the talc powder to a certain fineness to achieve the medicine or industrial reproduction.

Process of talcum powder processing:

After the large talc mine is crushed by the

jaw crusher, it is sent to the hopper by the bucket elevator, and is continuously fed into the

roller powder grinding mill main unit through the vibrating feeder. Blowing to the classifier for sorting by the action of the blower. The fine-grained talc powder is piped to the powder collector, and the unqualified particles are returned to the mill for grinding.

After

ultra-fine Raymond roller mill grinding, the ultra-fine talc powder not only has a special flaky structure, but also has a good solid luster. It can be used as an effective reinforcing material to impart high rigidity and creep resistance to plastics at both normal and high temperatures. In addition, the processing cost is not high, and the ultra-fine talcum powder can be mass-produced, successfully achieving the upgrading and innovation of the talc industry. Therefore, the highly efficient Raymond mill has brought a broad market prospect to the ultrafine talc industry.

The choice of talc powder mill is crucial in the production process of talcum powder, which directly affects the quality and use of talcum powder. The talc powder mill produced by

Shanghai Clirik Machinery Co.,Ltd has many types, complete functions and reliable quality, and the price of the mill is economical and reasonable.

Last:Ultra-fine roller mill and Raymond roller mill,which is more suitable for proces

Next:Why Chose Clirik YGM Raymond Roller Mill?