Raymond roller mill ring main unit working principle

From : clirik Date : 2019-01-15 14:09

Raymond roller mill ring main unit structure and working principle

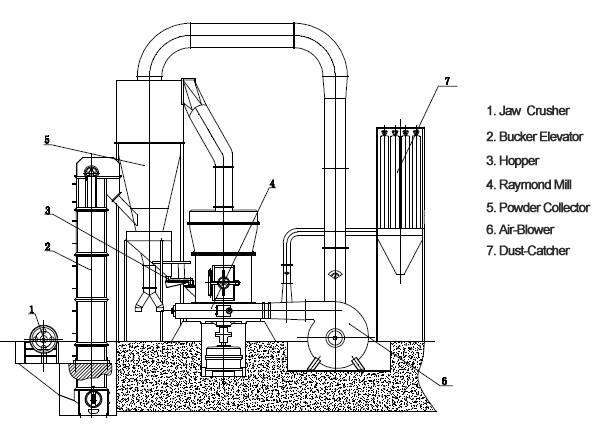

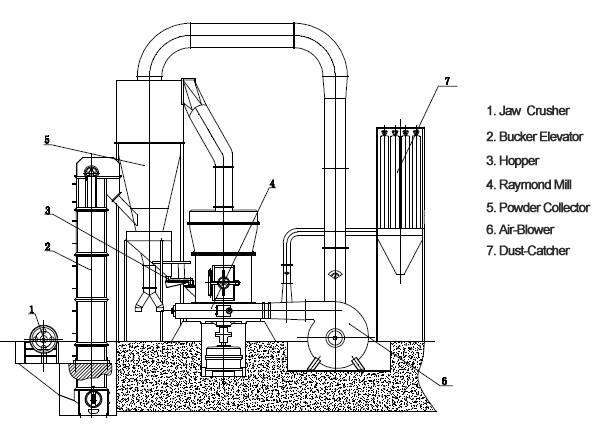

Raymond roller mill ring main unit needs the pulverized material to be uniformly and continuously sent into the three rollers grinder Raymond roller mill ring main unit main grinding chamber. Due to the centrifugal force during rotation, the grinding roller swings outward, pressing against the grinding ring, and the blade shovels the material to the grinding roller and the grinding ring. In the meantime, the grinding roller achieves the purpose of crushing.

After the material is ground, the grinding is carried into the analysis machine with the circulating air of the blower for sorting. The coarse and coarse material will be re-grinded, and the qualified fine powder will flow into the finished cyclone powder collector and be discharged through the powder discharging tube. For the finished product.

In the grinding chamber, there is a certain amount of moisture in the material to be ground, heat is generated during grinding, water vapor evaporates, and the pipelines of the whole machine are not tightly connected, the outside air is sucked in, the circulating air pressure is increased, and the mill is operated under negative pressure. The increased air flow is discharged into the dust remover through the residual air duct, and is purified and discharged into the atmosphere.

Raymond roller mill ring main unit advantage

The added sealing design of the equipment and the dust collector of various specifications will not cause dust, noise and other pollution, and it is more environmentally friendly.

The manufacture of parts such as grinding rolls and grinding rings is more ingenious, simplified vertical structure, and high-strength materials with high wear resistance and good toughness. The equipment can be operated continuously and work more efficiently.

three rollers grinder Raymond roller mill ring main unit uses multi-module intelligent control technology, which makes operation and management more convenient, covers a smaller area, and the process is smoother, saving time and effort.

Clirik Machinery Raymond roller mill ring main unit Applications

Clirik Machinery is widely used in barite, calcite, potash feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum. High-fine powder processing of more than 280 kinds of materials, such as glass, thermal insulation materials, etc., with a Mohs hardness of not more than 9.3 and a non-flammable and explosive mineral, chemical, construction and other industries with a humidity below 6%, R-type three rollers grinder Raymond roller mill ring main uniting The finished product has an arbitrary particle size ranging from 80 to 325 mesh, and some materials can be up to 600 mesh.

Last:Three rollers grinder price

Next:Raymond vertical roller mill repair