Which roller mill is used to produce 2000 mesh silicon powder?

From : clirik Date : 2018-12-15 15:50

Which superfine roller grinding mill is used to produce 2000 mesh silicon powder?

HGM series three-ring medium-speed superfine roller grinding mill is a kind of processing equipment for fine powder and ultra-fine powder. It adopts multiple grinder technology, with novel design and reasonable structure. It has small footprint, low power consumption and long operating life. The advantages of low cost and high cost performance of wearing parts.

Feed particle size: ≤20mm

Production: 0.5-45 tons / hour

Product performance advantage

1. Low investment efficiency

2. Loss and low fineness

Under the same fineness and power consumption of the finished product, the investment cost is lower than that of the jet mill, and the recovery period is short, but the output is about 45% higher. The wearing parts are made of wear-resistant materials, the service life is more than one year, and the finished product fineness can reach D97≤5μm.

3. Reliable environmental protection

There are no rolling bearings and screws in the grinding chamber, which avoids the problem that the bearing is vulnerable and the screw is loose and the equipment is destroyed. The pulse type dust collector is equipped with a silencer and a sound absorbing room to reduce dust and noise pollution, and the environmental protection effect is good.

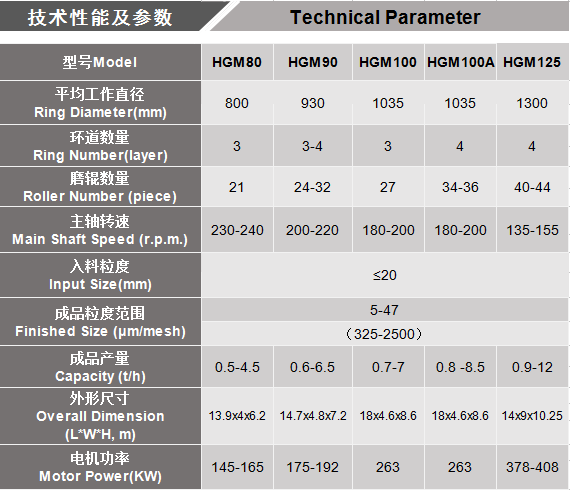

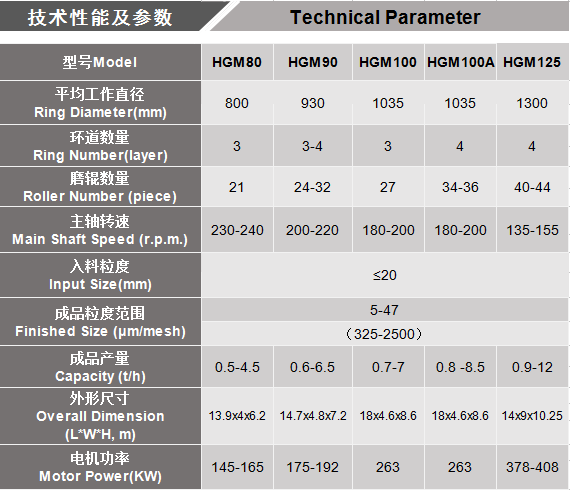

Product parameters:

Customer case

Anhui calcium powder factory

【client status】:

A calcium powder factory in Anhui purchased a medium-speed micro-grinding HGM100 from Clirik for deep processing of calcite. The equipment was put into operation in the second half of 2013, and the equipment is currently operating stably with low energy consumption. The finished product is good in size and the product is very popular. The customer is considering starting a new device.

【Production status】:

Processing materials: calcite Finished product fineness: 1250 mesh, 800 mesh

Zhejiang Mining Co., Ltd.

【client status】:

A mining company in Zhejiang Province introduced a Clirik medium-speed micro-grinding HGM80 for deep processing of kaolin. The medium-speed micro-grinding investment has low investment efficiency. Under the same fineness and power consumption of the finished product, the investment cost is lower than that of the jet mill, the recovery period is short, and the output is about 45% higher.

【Production status】:

Processing material: kaolin finished product fineness: 800 mesh

Last:Bauma Exhibition Is Coming

Next:Advantages of Clirik Grinding Roller Mill in Titanium Dioxide Powder Making