For Non-metallic Mines:Raymond Roller Mill is The Mr Right

From : clirik Date : 2018-09-29 11:14

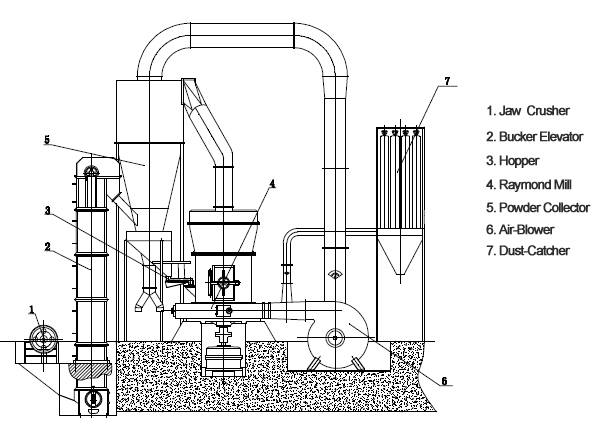

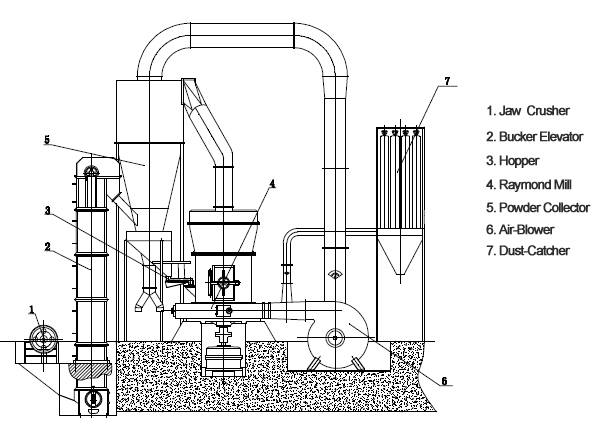

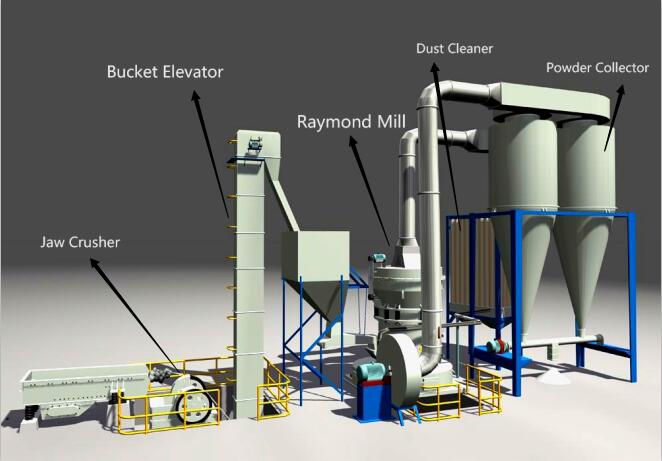

Raymond roller mill, also known as suspension roller grinding mill, is mainly composed of feeder, grinding roller, grinding disc, transmission mechanism, separator, etc. It is an important grinding equipment in the process of non-metallic mineral processing.

▲Raymond roller mill structure diagram

1. How Raymond roller mill works

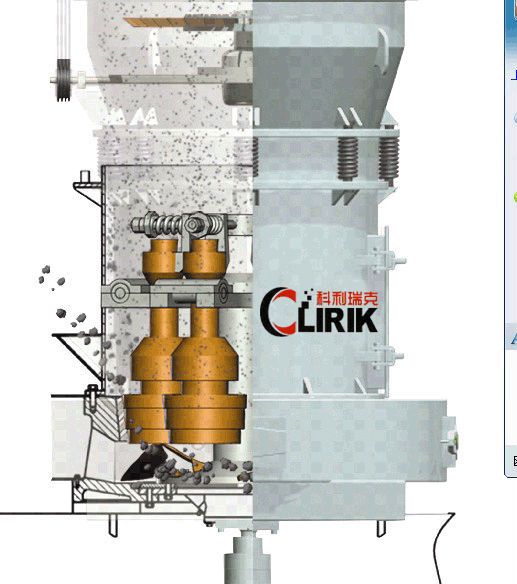

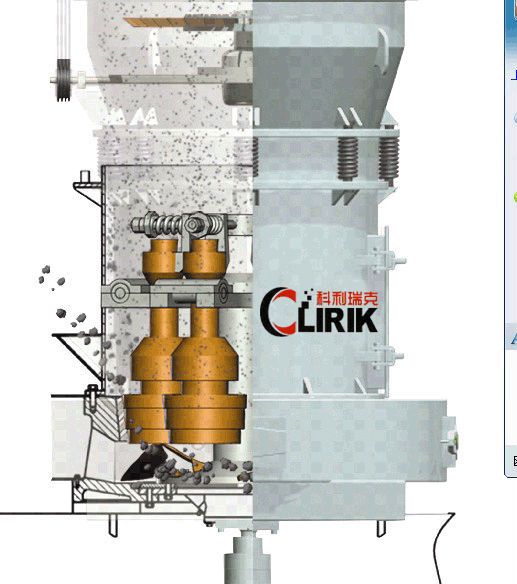

The working principle of Raymond roller mill is to add the material to be pulverized from the feeding hopper on the side of the hood to the machine, and to revolve around the vertical axis by the grinding roller device suspended on the main plum frame of the main machine, while rotating itself, due to the rotation By the action of the centrifugal force, the grinding roller swings outward and presses against the grinding ring, so that the blade shovel the material to the grinding roller and the grinding ring, and the purpose of pulverizing the material is achieved by the rolling and rolling of the grinding roller.

▲Raymond roller mill working principle

The wind classifier is a single or double row impeller classifier driven by a separate motor. In order to improve the classification efficiency and adjust the classification particle size in a wide range, a double-row impeller classifier can be used. The higher the rotational speed of the impeller, the finer the fractional particle size.

2. Features of Raymond roller mill

The air centrifugal classifier set by Raymond roller mill has a certain sorting effect on the ore particles with different density and hardness. That is, the purity of the fine grain product after the fine grinding by Raymond roller mill has a certain degree of improvement compared with the original ore ratio. It is important for the fine grinding of non-metallic minerals.

In addition, if hot air is fed, Raymond roller mill can also be used as a combination of grinding and drying. The feed water can reach 10%-12%, and the moisture of the product is close to zero.

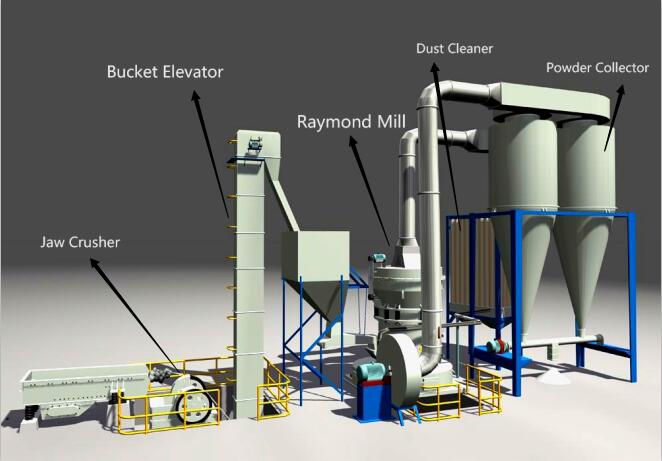

▲Raymond roller mill typical production process configuration

Although different types of Raymond roller mills have their own advantages, performance characteristics are not the same, but generally Raymond roller mill has the following characteristics:

The entire Raymond roller mill has a vertical structure, a relatively small footprint, a strong system, and a complete set of products. Whether it is rough processing or conveying of raw materials, milling and final packaging, it can be self-contained. system.

Compared with other milling equipment, Raymond roller mill has a high screening rate, and the finished grain size screening rate after Raymond grinding can reach more than 99%, which is not achieved by other milling equipment.

The electromagnetic vibrating feeder is uniform in feeding, easy to adjust, small in size, light in weight, energy-saving and power-saving, and easy to maintain.

The electric control adopts centralized control and advanced selection, and can realize unmanned operation in the host computer room.

The main drive unit adopts a closed reducer, which has stable transmission, reliable operation and no leakage of oil.

The main blade holder is always in contact with the material during operation, so the blade holder is composed of two upper and lower parts, and the lower part is worn and the disassembly connection bolt can be changed.

The important parts of Raymond roller mill are made of high-quality castings and profiles. The craftsmanship and rigorous process ensure the durability of the whole set of equipment.

3. Application range of Raymond roller mill

Raymond roller mill has the advantages of stable performance, simple process, convenient operation, large processing capacity and adjustable product size. It is widely used in calcite, marble, chalk, limestone, talc, wollastonite, gypsum and hard kaolinite. , clay, feldspar, barite, bentonite, graphite, tremolite, illite, sericite, glass, manganese ore, titanium ore, copper ore, chrome ore, refractory, insulation, clay, titanium dioxide, iron oxide High-fine powder processing of more than 300 materials such as non-flammable and explosive minerals, construction, chemical, fertilizer and other industries with a Mohs hardness of 9.3 or less and a humidity of 6% or less. The finished product has a particle size of 60-325 mesh ( In the range of 0.125 mm - 0.044 mm), the minimum fineness of a small part of the material can be up to 1000 mesh (0.013 mm) as needed.

4. Application of Raymond roller mill in Non-metallic Mineral Processing

(1) Calcium carbonate

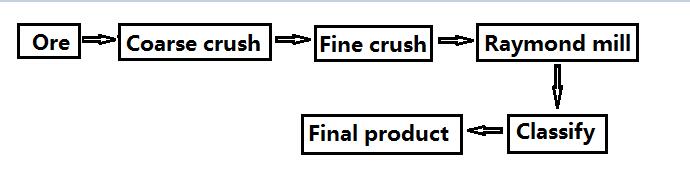

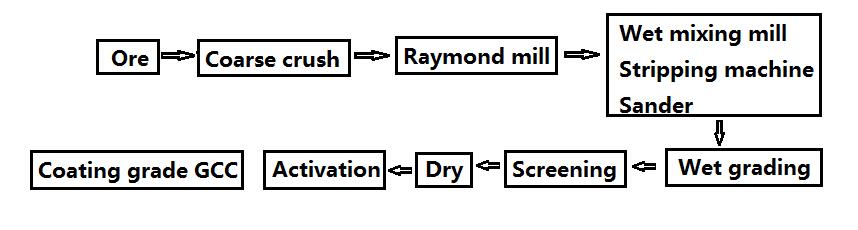

For ordinary calcium carbonate processing, Raymond roller mill can be directly processed into finished products of desired fineness; for ultra-fine calcium carbonate processing, Raymond roller mill can be used as pre-grinding equipment to provide raw materials for subsequent ultra-fine grinding operations.

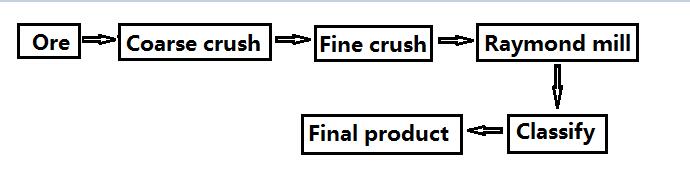

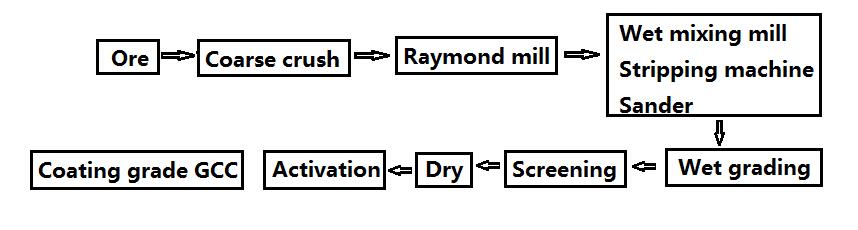

▲Raymond roller mill produces ordinary heavy calcium carbonate principle process

▲Raymond roller mill as a pre-grinding equipment to produce coating grade calcium process

For example, a company in Guilin, Guangxi, uses Raymond roller mill to produce heavy calcium carbonate fine powder. The feedstock has a feed size of about 10 mm and a production capacity of 850 kg/h, which can produce 800-1250 mesh calcium products.

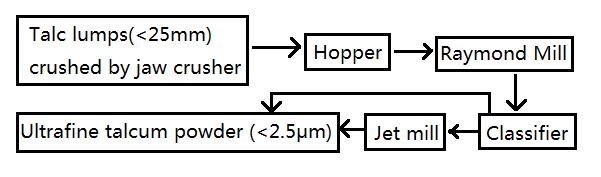

(2) Talc

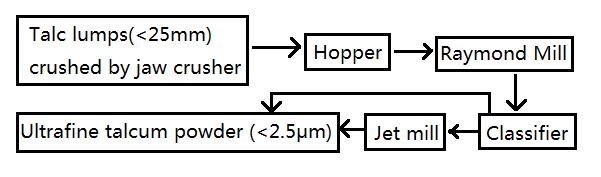

At present, the pulverization processing of talc mainly adopts a dry process, and the Raymond roller mill is matched with a jet mill, and is also used for ultrafine crushing of talc.

▲Raymond roller mill and airflow crushing together to produce ultra-fine talcum powder

The -100mm ore from the mine was crushed to -25mm with a jaw crusher and transported to the crushing workshop through a belt conveyor in the intermediate compartment. In the first stage of the crushing workshop, the Raymond roller mill is used for pulverization, and after the product is classified, the coarse particles are pulverized into a group of jet mills; the fine particles are combined with the jet milled product to become the final product. The ultrafine powder produced has a particle size of -2.5 μm.

5. Raymond roller mill's future development trend

In recent years, China's milling equipment industry has developed very rapidly. First, product development has changed from imitation to independent innovation. Second, economic operation has changed from extensive to efficient. With the continuous development of the powder industry, the market demand for Raymond roller mill is also increasing. As the main grinding equipment in China's powder industry, Raymond roller mill is inevitable in the development of “reliability, energy saving, precision and automation” in order to meet the requirements of different application fields.

(1) Energy saving and environmental protection

With the increasingly strict requirements of green environmental protection, Raymond roller mill's R&D and manufacturing should pay more attention to high-efficiency and energy-saving research, and improve the manufacturing of key points such as zero pollution, high efficiency, low energy consumption and mechanical life. As far as the Raymond roller mill market is concerned, energy-saving and environmental protection equipment with large processing capacity, high sorting efficiency and low energy consumption will be more popular, and the market demand is more urgent.

(2) Automatic control

In the future, non-metallic mineral powder processing, intelligentization and automation are inevitable trends. High reliability, precision, automatic condition monitoring and automatic control will gradually become the basic requirements of Raymond roller mill, and automatic control can effectively improve Raymond roller mill. Productivity, precision and safety.

(3) High grinding precision

With the continuous improvement of the fineness requirements of powder products in the application field, the milling equipment industry is bound to develop in the direction of refinement and scale, and Raymond roller mill is no exception.

According to the above-mentioned shortcomings of Raymond Mill, we have developed

HGM series ultra-fine grinding mill, which is more environmentally friendly and more automated than Raymond Mill. The grinding precision can reach 2500 mesh.

Last:Pyrophyllite Powder Grinding Test for South Korea Client with HGM Ultrafine Roll

Next:What Is The Price of A Raymond Roller Mill